PRODUCTOS

Jinyuan Mining Machinery

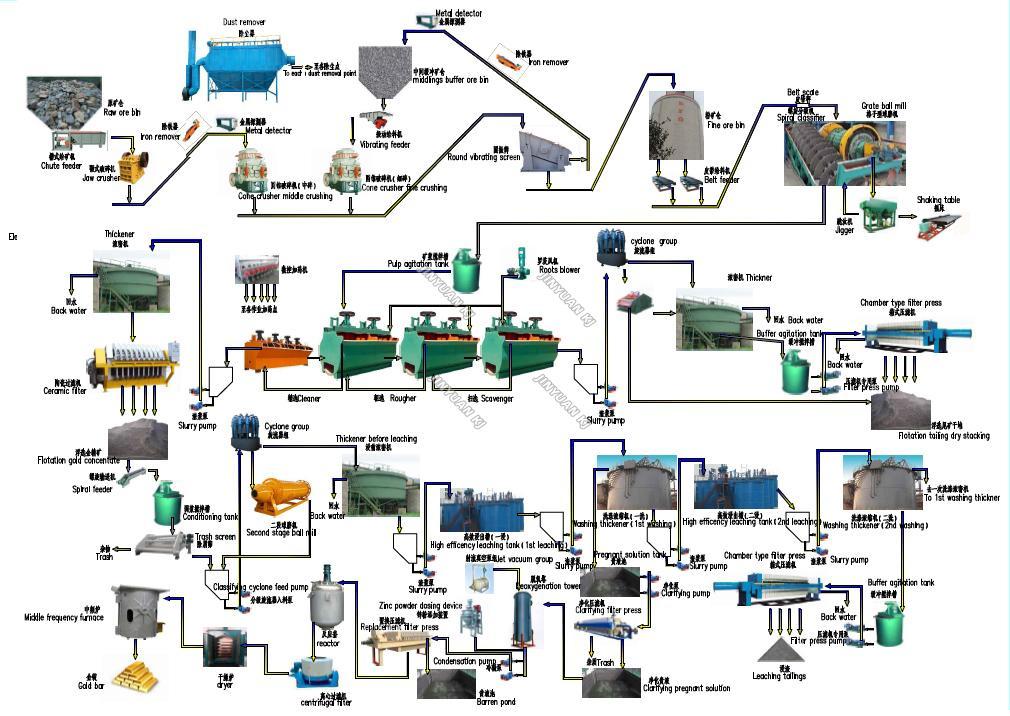

Zinc dust precipitation process flowsheet

Resumen: Una empresa especializada que integra investigación experimental, diseño de procesos, fabricación de equipos, instalación y puesta en marcha, y capacitación de personal.

Palabra Clave:

Mining Machinery

Categoría:

·Correo electrónico:yantaijinyuan@vip.163.com

Detalle del Producto

Technical process introduction

Zinc dust precipitation is one of the earlier application cyanidation. Firstly , cyanide is added in the pulp to leach the gold ore, after solid-liquid separation, the liquid adding zinc powder (including pregnant solutions) or zinc wire through chemical reaction to make gold and silver precipitation in gold, gold mud containing gold and silver is higher for smelting high purity gold ingot. The process is still widely used for gold extraction by cyanidation in flotation gold concentrate.

Technical process flowsheet

1.Agitation leaching - The leaching of gold is mainly realized in the leaching tank. The

slurry containing cyanide is strongly stirred under the action of impeller and compressed air, which is conducive to improving the leaching effect.

2.Countercurrent washing --commonly used process in cyanidation plant, usually

using type of several sets of single-layer or multi-layer thickener, the role of countercurrent washing is to use the overflow water of next thickener to the thickener, so as to "dilute" pulp, making the gold grade of liquid gradually reduced until the established standard. Countercurrent washing is the process of dilution and concentration of pulp.

3、Zinc powder replacement -- it is the process of adding metal reducing agent (zinc powder) to cyanide pregnant liquid and precipitating gold and silver into gold mud through chemical reaction, which usually includes deoxidation of pregnant liquid, adding zinc powder and lead acetate, and producing gold mud through filter pressing.

Process flow diagram

Productos Relacionados

Mensaje